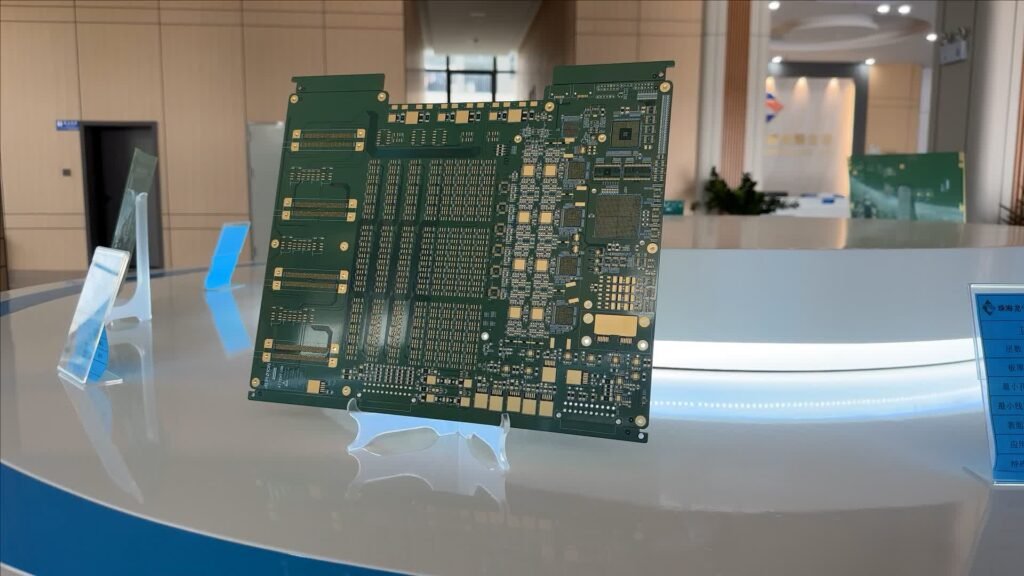

The color of a printed circuit board (PCB) is not just about aesthetics; it directly influences the production process, functionality, and usability of the final product. Choosing the right solder mask color can affect visual inspection, heat management, and even brand identity.

In this guide, we will explore the factors to consider when selecting a solder mask color, highlighting how each color can benefit different applications.

Understanding the Importance of Solder Mask Color

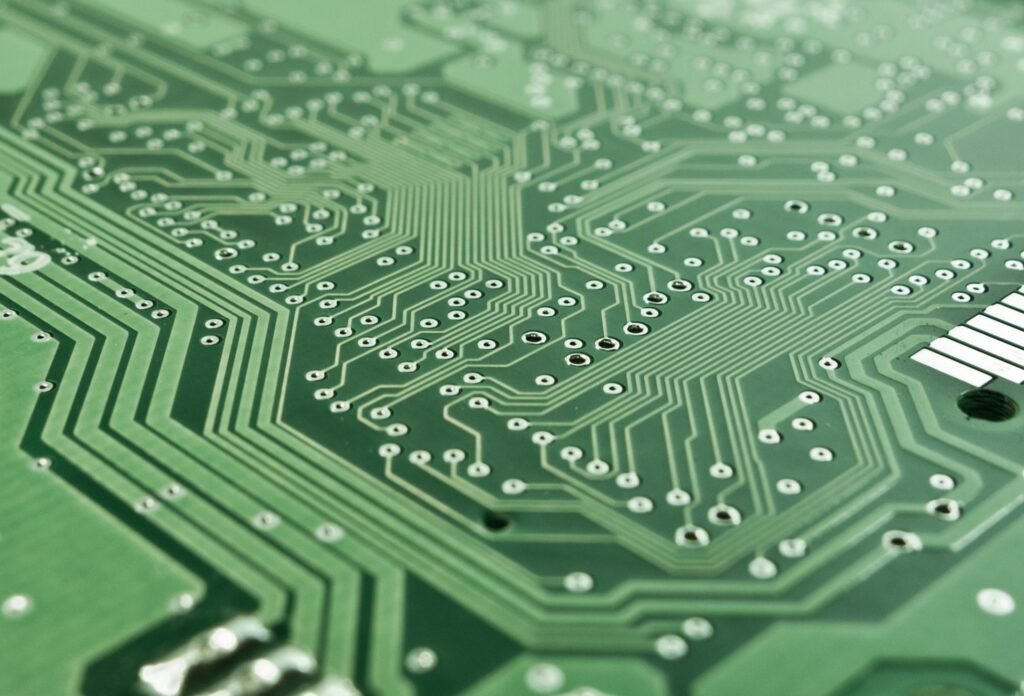

The solder mask acts as a protective layer that shields the copper traces on a PCB from oxidation, contamination, and solder bridging.

While green remains the most widely used color, other colors such as red, blue, black, white, and yellow are becoming increasingly popular for specific application

Key Functions of Solder Mask:

Electrical Insulation: Prevents unintentional connections between traces.

Oxidation Prevention: Shields copper from environmental exposure.

Visual Identification: Aids in component placement and error detection.

Aesthetic Appeal: Enhances the professional look of the final product.

How Does Solder Mask Color Affect PCB Performance?

Although the color itself does not directly impact electrical performance, it can influence visual inspection, thermal management, and brand presentation. Let’s explore some of the critical aspects.

2.1 Visual Inspection and Debugging

Green solder masks are preferred for manual inspection due to their high contrast with white silkscreen. This helps technicians quickly identify components and traces.

Best Choice for High-Visibility Applications: Green and blue.

Less Suitable Colors: Black and white, due to poor contrast.

Example:

When diagnosing faults on a PCB with black solder mask, identifying solder joints and traces becomes significantly more challenging compared to green PCBs.

2.2 Heat Management and Thermal Performance

The thermal characteristics of a solder mask color are often overlooked. Darker colors, such as black, tend to absorb more heat, while lighter colors, like green or white, are better at reflecting heat. This distinction can be crucial for high-power applications.

| Color | Heat Absorption | Thermal Stability | Typical Use Cases |

|---|---|---|---|

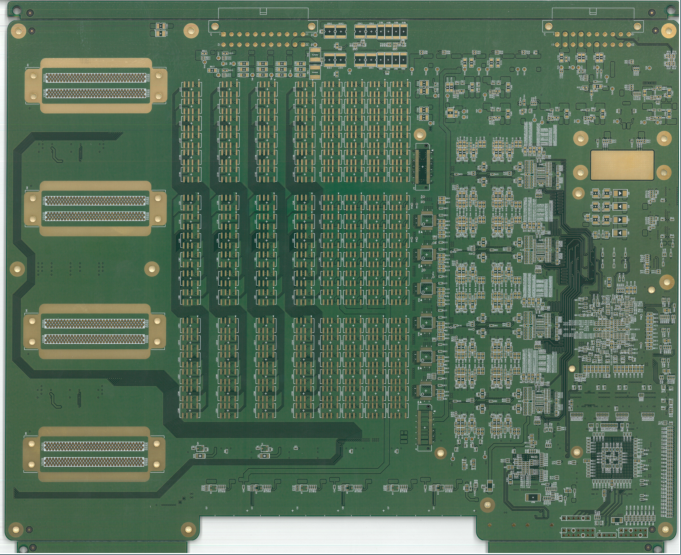

| Green | Moderate | High | General electronics, industrial automation |

| Red | Low | Medium | Consumer gadgets, prototyping |

| Blue | Moderate | High | Communication equipment, embedded systems |

| Black | High | Low | Audio devices, premium hardware |

| White | Low | Medium | LED lighting, display technology |

Factors to Consider When Choosing Solder Mask Color

Different PCB applications demand varying levels of visibility, heat resistance, and aesthetic appeal. Here are the primary factors to consider:

3.1 Application-Specific Requirements

The end application plays a significant role in deciding the solder mask color.

Industrial Automation: Green, due to cost-effectiveness and visibility.

Consumer Electronics: Red or black, for a premium look.

Medical Devices: White, for a clean and hygienic appearance.

Telecommunication Hardware: Blue, representing stability and reliability.

3.2 Environmental Factors

When selecting a solder mask color, consider the operating environment:

High-Temperature Conditions: Avoid black; opt for blue or green.

Humid or Moist Environments: Blue masks, as they resist moisture better.

High-Visibility Needs: Use yellow or red, which are easily distinguishable.

3.3 Aesthetic and Branding Considerations

Brand identity often dictates solder mask color choice.

Corporate Branding: Some companies consistently use specific colors to maintain a uniform brand image.

Component Identification: Red masks are often used for prototypes to indicate development stages.

Premium Product Lines: Black masks give a sleek and modern look.

Practical Tips for Solder Mask Color Selection

Here are some practical tips to ensure your PCB color choice aligns with your project needs:

4.1 Conduct a Visual Inspection Test:

Print a mockup of the PCB design in the chosen color and assess its readability and component visibility.

4.2 Simulate Thermal Conditions:

Test how the chosen color performs under thermal cycling to ensure it does not compromise the board’s integrity.

4.3 Align with Brand Guidelines:

For consumer-facing products, choose colors that align with your brand’s visual identity.

FAQs on Choosing Solder Mask Color

Q1: Does the color affect the PCB’s functionality?

No, the color itself does not impact electrical performance. However, it can affect thermal management and visual inspection.

Q2: Why do most PCBs use green solder masks?

Green solder masks offer optimal contrast with silkscreen printing and are cost-efficient to produce.

Q3: Can I customize the solder mask color for my project?

Yes, many manufacturers offer custom colors, but this may increase costs and production time.

Making the Right Choice for Your PCB

Selecting the correct solder mask color requires careful consideration of visual clarity, thermal stability, branding, and application requirements.

While green remains the standard, exploring alternative colors can help you meet specific functional and aesthetic goals.

Whether prioritizing heat management or visual inspection, your choice should always align with the intended application and environmental factors.