Choosing the right PCB finish is crucial for ensuring reliable performance and longevity. Different finishes suit different applications, depending on factors like environmental conditions, solderability, and cost.

At Longyu PCB, we help our clients choose finishes that match their specific needs. In this guide, we will explore the most common PCB finishes, their applications, and how to make the best choice for your project.

1. What Is PCB Finish and Why Does It Matter?

A PCB finish is a protective layer applied to copper traces. It prevents oxidation, enhances solderability, and improves electrical conductivity. The right finish helps maintain signal integrity, reduces corrosion, and ensures reliable connections during soldering.

Choosing the wrong finish can lead to issues like poor solder joints, signal loss, and even PCB failure.

1.1 Key Reasons for Choosing the Right Finish

The finish directly affects how the PCB performs in its intended environment. For example, automotive electronics often face temperature fluctuations and vibrations. In such cases, a durable finish like ENIG (Electroless Nickel Immersion Gold) works best. On the other hand, consumer electronics benefit from cost-effective finishes like HASL (Hot Air Solder Leveling).

Learn more about industry standards from the IPC-6012 Standard.

2. Types of PCB Finishes: Pros, Cons, and Applications

2.1 HASL (Hot Air Solder Leveling)

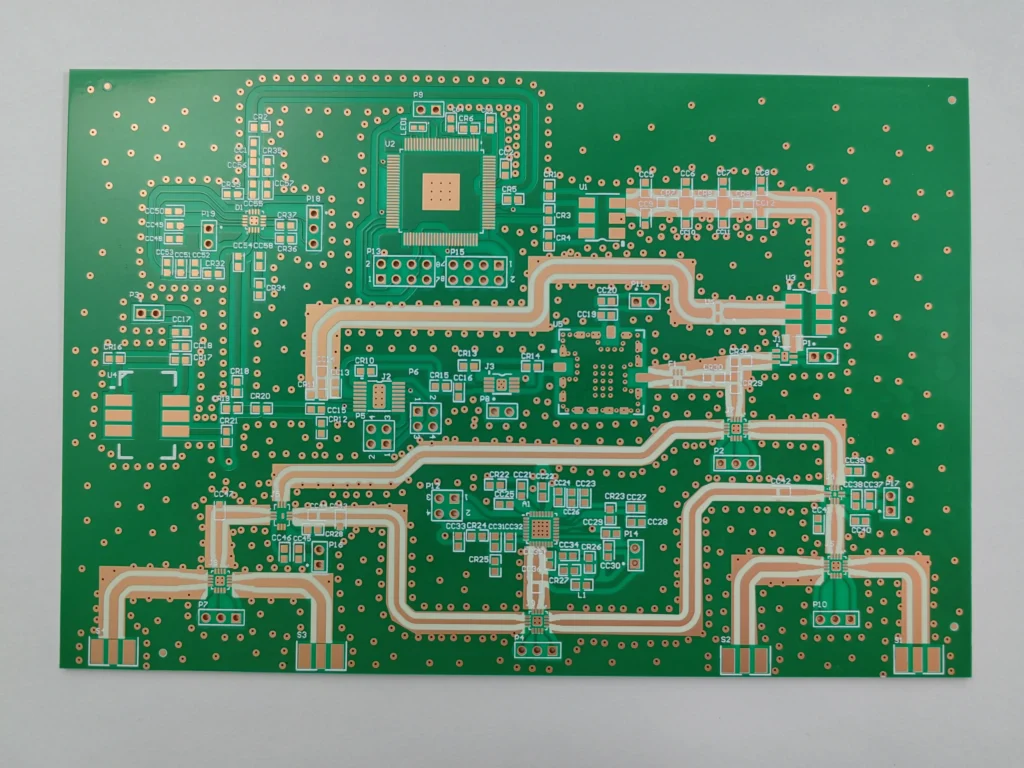

HASL is one of the most popular PCB finishes. It involves dipping the board in molten solder and then using hot air to level the surface. This creates a thin, solderable layer on the copper traces.

Pros: Low cost, good solderability.

Cons: Uneven surface, not ideal for fine-pitch components.

Applications: Suitable for low-cost electronics like multimedia and basic communication devices.

2.2 ENIG (Electroless Nickel Immersion Gold)

ENIG uses a layer of nickel topped with a thin layer of gold. The gold protects the nickel and provides a flat surface for soldering. It is known for its durability and resistance to oxidation.

Pros: Flat surface, good for fine-pitch components, excellent corrosion resistance.

Cons: Higher cost compared to HASL.

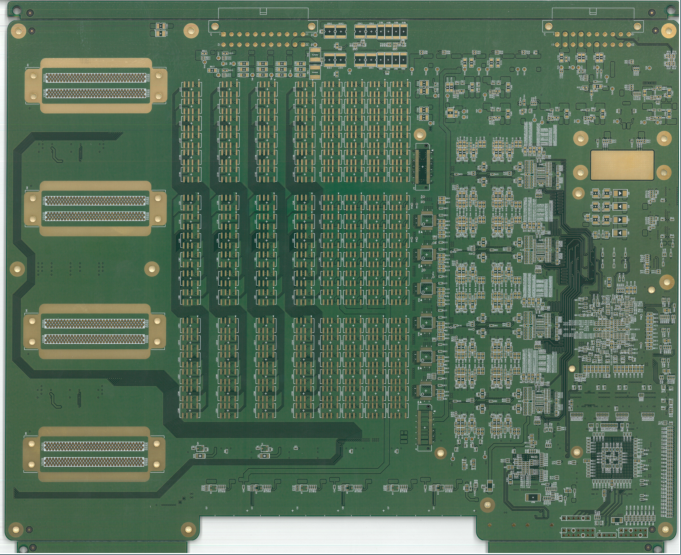

Applications: Ideal for automotive electronics, medical devices, and high-density communication boards.

2.3 OSP (Organic Solderability Preservative)

OSP applies an organic film over copper to protect it from oxidation. It is a lead-free and environmentally friendly option but has a limited shelf life.

Pros: Low cost, eco-friendly.

Cons: Limited durability, only suitable for single soldering processes.

Applications: Best for consumer electronics and short-lifecycle devices.

2.4 Immersion Silver

Immersion Silver provides a smooth, solderable surface with excellent conductivity. However, it can tarnish if not stored properly.

Pros: Flat surface, good for high-frequency applications.

Cons: Susceptible to environmental degradation.

Applications: Used in communication systems and high-speed data transfer devices.

2.5 Immersion Tin

This finish creates a flat, solderable surface and is compatible with fine-pitch components. However, it is prone to forming tin whiskers.

Pros: Cost-effective, good solderability.

Cons: Limited shelf life, risk of whiskering.

Applications: Suitable for industrial medical devices and multimedia applications.

3. How to Choose the Right PCB Finish: Key Factors to Consider

3.1 Application Environment

Environmental conditions play a major role in finish selection. For example, automotive electronics face high temperatures and vibrations. Therefore, robust finishes like ENIG are preferred. In contrast, indoor multimedia devices, which do not face harsh conditions, can use cost-effective finishes like HASL.

3.2 Solderability and Durability

Reliable solder joints are crucial for long-term performance. Finishes like ENIG and Immersion Silver offer good solderability, even with fine-pitch components. In contrast, HASL may cause uneven surfaces, leading to soldering issues in high-density designs.

3.3 Cost Considerations

Budget plays a vital role. For high-volume consumer electronics, HASL or OSP can save costs. However, for critical applications like medical devices, investing in ENIG is wise due to its reliability.

Explore cost factors in our guide on PCB Manufacturing Cost Breakdown.

4. Real-World Applications of PCB Finishes

4.1 Automotive Electronics

PCBs in vehicles must withstand temperature changes and mechanical stress. ENIG is commonly used because it resists oxidation and maintains good solderability over time.

4.2 Medical Devices

For medical devices, especially those used in critical environments, ENIG ensures stable performance and corrosion resistance.

4.3 Communication Systems

High-frequency boards benefit from Immersion Silver, which offers flat, conductive surfaces that minimize signal loss.

Make Informed Choices with Longyu PCB

Choosing the right PCB finish depends on the application, environment, and budget.

At Longyu PCB, we guide our clients to select finishes that match their needs. Whether you need reliable automotive electronics or cost-efficient multimedia PCBs, we provide expert advice and high-quality finishes.