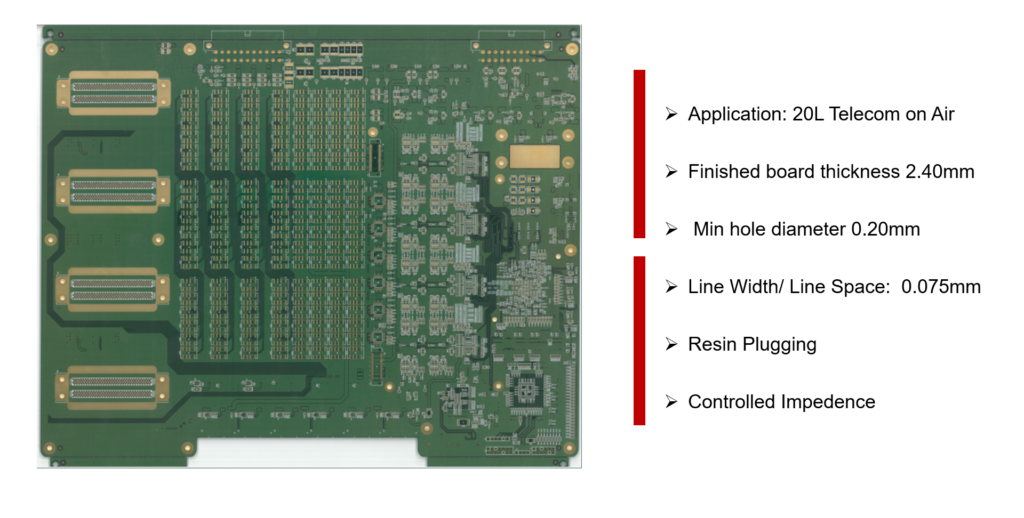

At Longyu PCB, we know that maintaining PCB quality is crucial for long-lasting performance.As a professional PCB manufacturer, we focus on practical maintenance strategies that extend the lifespan of your boards.

In this article, we will share essential tips to keep your PCBs reliable. From cleaning methods to thermal management, our insights will help you maintain optimal performance in various applications.

1. Regular Cleaning: Maintaining Optimal Performance

Dirt, dust, and debris accumulation on PCBs can compromise signal integrity and lead to overheating. Regular cleaning is crucial for maintaining optimal performance, especially in industrial environments.

1. Regular Cleaning: Maintaining Optimal Performance

Dirt, dust, and debris accumulation on PCBs can compromise signal integrity and lead to overheating. Regular cleaning is crucial for maintaining optimal performance, especially in industrial environments.

1.1 Cleaning Techniques

The cleaning method depends on the type of contamination:

- Dry Cleaning: Use compressed air to remove dust and loose particles.

- Wet Cleaning: Isopropyl alcohol (IPA) can dissolve grime and oil.

- Ultrasonic Cleaning: Ideal for removing flux residues from assembled boards.

1.2 Cleaning Precautions

Always ensure that the PCB is powered off and disconnected from any power source before cleaning. Use anti-static tools to avoid electrostatic discharge (ESD) damage.

For detailed cleaning standards, refer to the IPC-5704 Standard on PCB cleanliness.

2. Preventing Moisture and Corrosion: Environmental Protection

Moisture is one of the leading causes of PCB failure. It can lead to corrosion, reduced conductivity, and even short circuits.

2.1 Moisture Prevention Techniques

- Conformal Coating: A thin polymer layer protects the PCB from moisture, dust, and contaminants.

- Sealed Enclosures: Use IP-rated housings to protect against environmental factors.

- Desiccant Packs: Place moisture-absorbing packs in storage areas to keep PCBs dry.

2.2 Corrosion Control

Apply anti-corrosive coatings on exposed copper surfaces. Regularly inspect solder joints for signs of oxidation and apply flux where necessary.

3. Thermal Management: Keeping Heat Under Control

Overheating can severely damage PCBs, leading to material degradation and solder joint failures. Implementing effective thermal management techniques is essential for long-lasting performance.

3.1 Heat Dissipation Techniques

- Heat Sinks: Attach to high-power components to dissipate excess heat.

- Cooling Fans: Improve air circulation, especially in enclosed environments.

- Thermal Pads: Transfer heat from components to heat sinks efficiently.

3.2 Monitoring Temperature

Regularly monitor PCB temperature using thermal imaging to detect hotspots. Integrating temperature sensors within the PCB design can facilitate real-time monitoring.

4. Proper Handling: Minimizing Physical Stress

Improper handling during installation or maintenance can cause PCB damage, including trace breaks and delamination.

4.1 Handling Guidelines

- Anti-Static Measures: Use ESD-safe gloves and mats during handling.

- Avoid Bending: Never flex the PCB as it can crack internal layers.

- Proper Mounting: Use appropriate fasteners to secure the board without over-tightening.

4.2 Storage Best Practices

Store PCBs in anti-static bags to protect against dust and static. Keep the storage area free from moisture and temperature fluctuations.

5. Periodic Testing: Ensuring Ongoing Reliability

Regular testing identifies potential issues before they escalate, ensuring continuous reliability.

5.1 Recommended Tests

- Impedance Testing: Verifies that signal paths are within specified parameters.

- Flying Probe Testing: Detects open circuits and short circuits.

- Thermal Cycling Test: Checks for thermal expansion issues.

5.2 Maintenance Logs

Maintain a log of test results and inspection dates. Tracking performance over time helps in early fault detection.

6. Firmware and Software Maintenance: Keeping Systems Up to Date

Outdated firmware can cause compatibility issues, leading to system malfunctions.

6.1 Regular Updates

Ensure firmware is regularly updated to patch vulnerabilities and improve performance. Use version control systems to manage updates.

6.2 Calibration and Configuration

Regularly recalibrate sensors and configure settings to align with updated software versions.

7. Documentation and Training: Building Maintenance Awareness

Proper training for maintenance personnel reduces human error and ensures consistent PCB care.

7.1 Creating Maintenance Protocols

Develop comprehensive documentation outlining cleaning procedures, testing schedules, and handling precautions.

7.2 Staff Training

Conduct regular training sessions on best practices for PCB handling and maintenance.

Extending PCB Lifespan Through Proactive Maintenance

Maintaining PCBs through regular cleaning, proper handling, thermal management, and periodic testing significantly extends their lifespan. By implementing these practical tips, manufacturers and users can minimize failures and maintain optimal device performance.

Learn More About Reliable PCB Maintenance with Longyu PCB

Discover more maintenance strategies and professional guidance at Longyu PCB and enhance the durability of your PCBs.