The PCB industry is evolving rapidly, driven by advancements like 5G, IoT, EVs, and AI. To stay competitive, manufacturers must adopt new technologies and innovative practices.

Longyu PCB leverage cutting-edge solutions to meet these changing demands, ensuring high-quality, reliable PCBs for various industries. This guide highlights key trends shaping the PCB landscape in 2025, offering practical insights for engineers, manufacturers, and procurement professionals.

1. Emerging PCB Technologies: Next-Gen Innovations

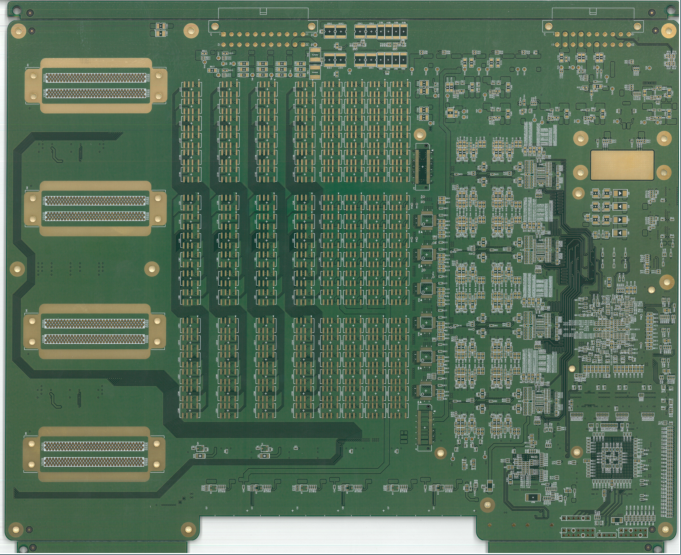

1.1 High-Density Interconnect (HDI) PCBs

As electronic devices become increasingly compact and multifunctional, the demand for High-Density Interconnect (HDI) PCBs continues to rise. HDI technology integrates more components on smaller board areas, making it essential for high-performance devices.

Key Features of HDI PCBs:

| Feature | Description | Benefit |

|---|---|---|

| Microvias and Blind/Buried Vias | Enable efficient signal routing and space reduction. | Higher component density, better performance. |

| Layer Interconnects | Enhance signal integrity by minimizing trace lengths. | Reduced signal loss and improved reliability. |

| Fine Line Traces | Support high component density without sacrificing performance. | Optimal for compact electronic devices. |

Applications:

- Consumer Electronics: Smartphones and wearables benefit from HDI’s compact design.

- Automotive Electronics: Advanced Driver Assistance Systems (ADAS) require dense circuitry.

- Telecommunication: 5G network infrastructure relies on HDI for high-speed data processing.

Market Outlook:

According to a report from Market Research Future, the global HDI PCB market is expected to grow at a CAGR of 20% from 2023 to 2030, driven by the proliferation of smart devices and the increasing adoption of IoT.

Case Study:

Leading PCB manufacturer Foxconn implemented advanced HDI production lines, achieving 30% higher density while reducing production costs by 20%. This innovation enhanced the reliability of smartphone PCBs.

1.2 Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs are gaining popularity due to their versatility and durability. These boards can withstand bending and flexing, making them ideal for dynamic and compact applications.

Why Flexible and Rigid-Flex PCBs Are Gaining Popularity:

| Advantage | Description | Application |

|---|---|---|

| Durability | Withstand repetitive motion and mechanical stress. | Medical devices, automotive electronics. |

| Lightweight Design | Suitable for portable and wearable electronics. | Smartwatches, foldable phones. |

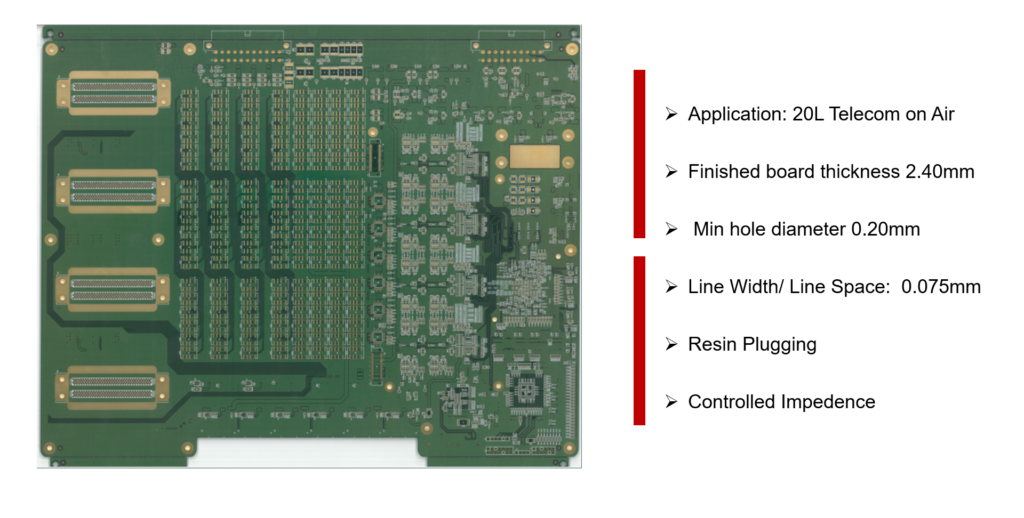

| Space Optimization | Combines flexible and rigid layers to maximize functionality. | Aerospace systems, compact consumer gadgets. |

Innovation Spotlight:

New materials like polyimide are enhancing flexibility while maintaining thermal resistance. This makes rigid-flex PCBs more reliable in fluctuating temperature environments.

Market Insight: According to Global Market Insights, the flexible PCB market is projected to reach $27 billion by 2027, driven by the growing demand for wearable and portable devices.

1.3 Advanced Materials: The Shift Towards High-Performance Substrates

To meet the demands of high-frequency and high-power applications, PCB manufacturers are increasingly using advanced materials with superior electrical and thermal properties.

Key Material Innovations:

| Material | Key Characteristics | Application |

|---|---|---|

| High-Tg Laminates | Withstand thermal stress, ideal for automotive electronics. | EV battery management systems. |

| Low-Dielectric Materials | Improve signal transmission at high frequencies. | 5G base stations, high-speed routers. |

| Conductive Polymers | Enhance thermal management while maintaining flexibility. | Industrial automation systems, flexible circuits. |

Industry Insight: According to IPC Standards, the adoption of high-Tg and low-loss materials is expected to grow by 30% over the next decade, driven by the rise of 5G and high-speed computing.

2. Smart Manufacturing: The Rise of Automation and AI

2.2 AI-Driven Quality Control

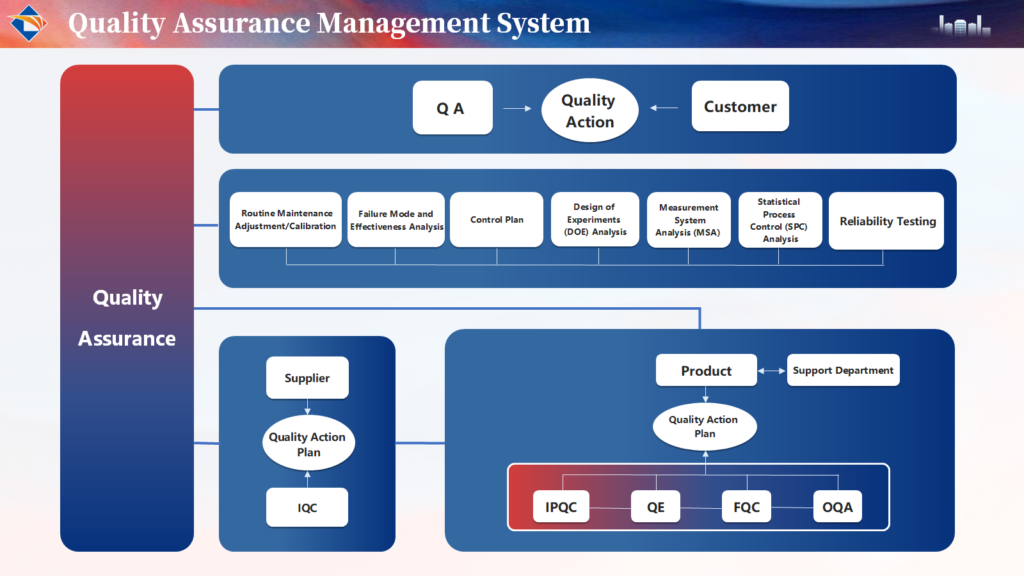

Artificial Intelligence (AI) is increasingly used in PCB manufacturing to enhance quality control. By analyzing vast amounts of production data, AI algorithms identify anomalies, predict potential failures, and ensure consistency in mass production.

Core Technologies:

- Machine Learning Models: Identify patterns linked to production defects.

- Image Recognition: Detects minute surface defects invisible to the human eye.

- Predictive Maintenance: Monitors equipment health to prevent unexpected breakdowns.

Benefits of AI-Driven Quality Control:

| Benefit | Description | Application |

|---|---|---|

| Reduced Downtime | Predictive insights help prevent unexpected failures. | Mass production lines in automotive electronics. |

| Higher Yield Rates | Early detection of defects minimizes waste and rework. | Consumer electronics and communication modules. |

| Enhanced Product Quality | Consistent output in batch production, reducing variability. | PCB manufacturing for critical applications. |

According to McKinsey & Company, integrating AI into PCB manufacturing can boost production efficiency by up to 40%.

3. Sustainability and Green Innovations in PCB Manufacturing

3.1 Eco-Friendly PCB Materials

With global environmental regulations becoming stricter, manufacturers are adopting sustainable PCB materials to reduce their carbon footprint and comply with green manufacturing standards.

Popular Green Materials:

| Material | Characteristics | Application |

|---|---|---|

| Halogen-Free Laminates | Eliminates toxic emissions, compliant with RoHS standards. | Consumer electronics, automotive systems. |

| Bio-Based Epoxy Resins | Derived from renewable resources, reduces carbon footprint. | Eco-friendly PCBs for sustainable products. |

| Lead-Free Solder Alloys | Complies with REACH and RoHS, minimizes environmental impact. | High-reliability industrial applications. |

Market Trend:

According to Sierra Assembly, around 60% of PCB manufacturers are shifting towards green materials to meet international compliance standards.

3.2 Reducing Carbon Footprint in PCB Production

Modern PCB manufacturers are increasingly focused on minimizing energy consumption and optimizing resource use. Sustainable practices not only align with environmental regulations but also reduce operational costs.

Key Practices:

- Smart Energy Management: Implement IoT-enabled monitoring to track energy consumption.

- Renewable Energy Integration: Utilize solar and wind power in manufacturing plants.

- Low-Emission Soldering: Apply low-temperature soldering techniques to save energy.

4. Challenges and Solutions in Future PCB Design

4.1 Managing High-Frequency Signals in 5G PCBs

The rise of 5G technology brings challenges related to signal integrity and electromagnetic interference (EMI). Maintaining performance in high-frequency environments requires advanced design techniques and materials.

Key Solutions:

- High-Frequency Substrates: Use materials like PTFE to minimize signal loss.

- EMI Shielding: Apply metal coatings to reduce interference.

- Differential Signal Traces: Maintain balanced transmission to reduce crosstalk.

Industry Insight:

According to IEEE, over 50% of 5G PCBs face challenges related to signal interference, requiring innovative materials and layout designs.

4.2 Heat Dissipation in High-Power Applications

Efficient thermal management is crucial for maintaining PCB performance, especially in high-power and high-frequency applications.

Cooling Techniques:

- Thermal Vias: Create heat paths to efficiently dissipate excess heat.

- Active Cooling Systems: Integrate fans and heat sinks for high-power components.

- Graphene-Based Heat Spreaders: Enhance thermal conductivity and reduce hot spots.

5. Market Outlook: Global Growth and Regional Focus (Continued)

1. Technological Advancements:

- 5G Expansion: The deployment of 5G networks increases demand for high-frequency PCBs with low signal loss.

- Electric Vehicles (EVs): As EV production grows, manufacturers require PCBs with enhanced heat dissipation and durability.

- Artificial Intelligence (AI): Complex computing requires PCBs with improved thermal management and signal integrity.

2. Policy and Compliance Trends:

- Green Manufacturing Regulations: Compliance with EU RoHS and REACH standards is crucial for accessing global markets.

- Localization Efforts: Countries are pushing for domestic PCB manufacturing to reduce supply chain risks.

3. Supply Chain Realignment:

- Reshoring Manufacturing: Companies are bringing production closer to end markets to reduce geopolitical risks.

- Diversifying Suppliers: Reducing dependence on a single region enhances resilience against disruptions.

According to Statista, the global PCB market is expected to reach $80 billion by 2030, driven by growth in automotive electronics and telecommunications.

6. Future Innovations Shaping the PCB Industry

6.1 Integration of Advanced Sensors

The increasing adoption of smart devices and IoT is driving the integration of sensors directly onto PCBs. This trend is particularly prominent in applications requiring real-time data collection and analysis.

Key Innovations:

| Sensor Type | Function | Application |

|---|---|---|

| Temperature Sensors | Monitor heat build-up in power electronics. | Battery management systems, industrial control units. |

| Vibration Sensors | Detect stress and mechanical fatigue. | Automotive and aerospace PCBs. |

| Pressure Sensors | Monitor fluid dynamics in cooling systems. | Hydraulic control boards. |

By embedding sensors directly onto the PCB, manufacturers reduce the need for additional components, saving space and improving data accuracy. This approach is becoming standard in smart healthcare devices and automotive control systems.

6.2 AI-Powered PCB Design Optimization

Artificial Intelligence (AI) is increasingly used to enhance PCB design processes, reducing errors and accelerating development. Integrating AI algorithms into CAD software allows for automated trace routing, component placement, and defect prediction.

Core Applications:

- Design Automation: AI algorithms optimize trace routing and via placement.

- Failure Prediction: Predicts potential faults during the design phase, reducing prototype iterations.

- Data-Driven Optimization: Uses machine learning to analyze production data and suggest improvements.

7. Conclusion: Embracing the Future of PCB Technology

The PCB industry is set to evolve significantly in the coming years, driven by advancements in HDI, flexible PCBs, smart manufacturing, and green innovations. Embracing these trends will enable manufacturers to meet the increasing demands for high-performance, sustainable, and reliable PCBs.

At Longyu PCB, we are committed to leveraging cutting-edge technologies to meet future challenges. By integrating AI-driven quality control and sustainable practices, we ensure that our products meet the highest standards of reliability and performance.

Stay ahead in the PCB industry with Longyu PCB. Contact us today to learn more about our innovative solutions.