Manufacturing a Printed Circuit Board (PCB) involves various processes, materials, and quality control measures that directly impact the overall cost.

Understanding these factors is crucial for designers, engineers, and procurement specialists aiming to optimize production budgets without compromising quality.

In this article, we will explore the key elements that influence PCB manufacturing costs and provide practical insights to help you make cost-effective decisions.

1. Material Selection: The Foundation of PCB Cost

The choice of material is one of the most significant factors affecting PCB cost. Different substrates and copper weights impact both the manufacturing complexity and the final price.

1.1 Substrate Material

Common substrate materials include FR-4, polyimide, Rogers, and CEM-3. FR-4 is the most widely used due to its cost-effectiveness and decent performance. However, specialized applications may require advanced materials:

- FR-4: Suitable for general electronic products, balancing cost and performance.

- Polyimide: Ideal for flexible PCBs, resistant to high temperatures.

- Rogers: Used for high-frequency applications, offering superior signal integrity.

1.2 Copper Thickness

The copper layer thickness affects the current-carrying capacity and thermal performance of the PCB. Standard copper weights include 1 oz/ft², 2 oz/ft², and higher for power applications. Thicker copper increases material cost and etching difficulty.

| Material | Properties | Typical Application |

|---|---|---|

| FR-4 | Good thermal and electrical properties | Consumer electronics |

| Polyimide | High flexibility and temperature resistance | Automotive and aerospace |

| Rogers | High-frequency stability | RF and microwave circuits |

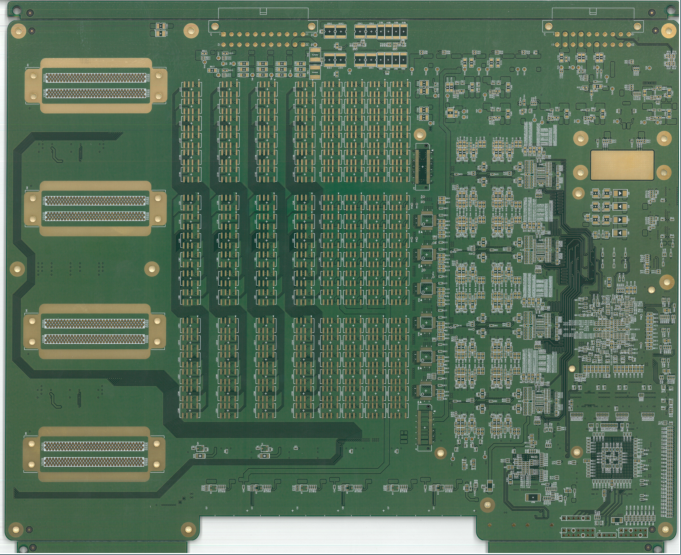

2. Layer Count: Adding Complexity and Cost

The number of layers in a PCB significantly affects manufacturing complexity and cost. Single-layer and double-layer boards are more affordable, while multilayer boards (4, 6, 8, or more layers) increase both material and processing costs.

2.1 Multilayer PCB Challenges

As layer count increases, the following complexities arise:

- Interlayer Alignment: Ensuring precision during lamination.

- Via Complexity: Adding buried or blind vias increases drilling costs.

- Signal Integrity: Requires careful layer stack-up design.

2.2 Balancing Cost and Performance

While more layers enable complex circuitry, they also require advanced lamination techniques and precise drilling. Consider whether the application truly requires additional layers or if a simpler design can meet the requirements.

3. Board Size and Dimensions: Space Matters

The physical dimensions of the PCB affect not only material consumption but also panel utilization. Inefficient use of the panel space leads to increased waste and costs.

3.1 Panel Optimization

Manufacturers often use standard panel sizes (e.g., 18″ x 24″) to maximize material utilization. Designing PCBs that efficiently fit within these dimensions reduces waste. Non-standard sizes may result in lower yield rates.

3.2 Tolerance Considerations

Smaller boards with tight tolerances require more precision during fabrication, increasing both time and cost. Consider adjusting the design to maintain manufacturability while minimizing wasted space.

4. Surface Finish: Balancing Cost and Performance

Surface finish protects the copper traces from oxidation and ensures solderability. Common finishes include HASL, ENIG, OSP, and Immersion Silver.

4.1 HASL (Hot Air Solder Leveling)

Cost-effective but may lead to uneven surfaces, unsuitable for fine-pitch components.

4.2 ENIG (Electroless Nickel Immersion Gold)

Widely used for high-reliability applications, offering a flat surface and good oxidation resistance but at a higher cost.

4.3 Choosing the Right Finish

The choice of surface finish should balance performance and cost based on the application requirements. For high-frequency applications, finishes like ENIG or Immersion Silver are preferred due to better signal integrity.

5. Drilling and Via Technology: Precision at a Cost

Drilling is a critical and cost-intensive step in PCB manufacturing. The type and number of vias greatly affect the cost, especially when using microvias or blind/buried vias.

5.1 Via Types

- Through-Hole Vias: Standard and cost-effective.

- Blind Vias: Connect inner layers to the surface, increasing complexity.

- Buried Vias: Internal connections that require advanced drilling methods.

- Microvias: Used in HDI (High-Density Interconnect) boards, costly but space-efficient.

5.2 Drill Accuracy and Cost

High-precision laser drilling for microvias significantly increases cost compared to traditional mechanical drilling. Optimize via placement to minimize drill count and complexity.

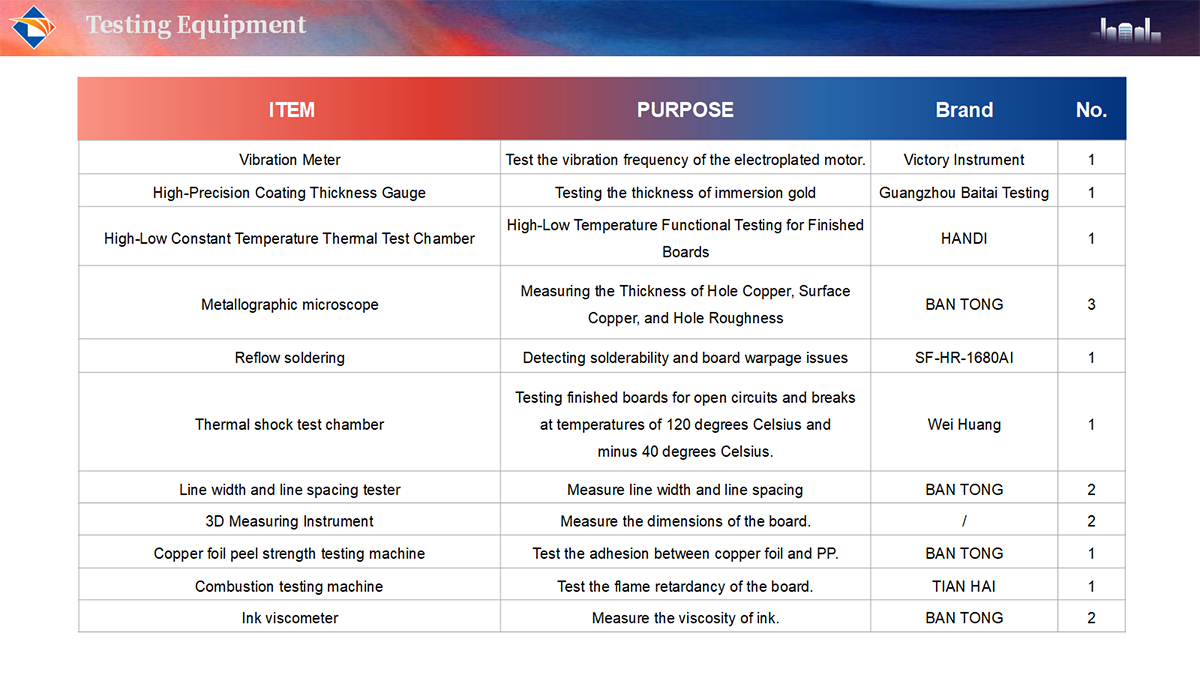

6. Quality Control and Testing: Ensuring Reliability

Post-production testing and quality assurance are essential to maintain reliability. Tests like AOI, flying probe, and functional testing add to the overall cost but are necessary to catch defects early.

6.1 Inspection Techniques

- AOI (Automated Optical Inspection): Detects surface defects.

- X-Ray Inspection: Checks internal layer alignment and solder joint quality.

- Flying Probe Test: Verifies electrical connectivity without a physical fixture.

6.2 Cost-Benefit Analysis

While testing increases upfront costs, it helps identify potential failures that could lead to costly recalls or warranty claims. Investing in comprehensive testing ensures long-term reliability.

7. Production Volume: Economies of Scale

Manufacturing in higher volumes reduces the per-unit cost due to setup amortization and bulk material purchases. Low-volume orders tend to be more expensive per board.

7.1 Prototype vs. Mass Production

Prototyping small batches often involves higher costs per unit due to the lack of scale and one-time setup charges. Planning for scalable production can reduce unit costs significantly.

Conclusion: Making Cost-Effective PCB Decisions

Understanding the factors affecting PCB manufacturing costs allows engineers to make informed decisions during the design and production stages. By carefully balancing material selection, layer count, surface finish, and testing requirements, it is possible to optimize both quality and cost.

For more insights, visit Longyu PCB for professional guidance.