FR4 dominates the PCB industry due to its reliable balance of performance, durability, and cost.

In this article, you’ll learn what FR4 is made of, how engineers use it in real-world circuit boards, and when to consider alternative materials for demanding applications.

What Is FR4?

FR4 is a glass-reinforced epoxy laminate that engineers widely use as the base material in printed circuit boards.

The “FR” stands for “flame retardant,” and “4” refers to the NEMA-grade classification. Manufacturers create it by combining woven fiberglass cloth with epoxy resin to form a strong, flame-resistant, and electrically insulating sheet.

You’ll find FR4 in nearly all rigid PCBs thanks to its excellent mechanical and thermal properties:

- High mechanical strength under pressure

- Thermal stability up to 150°C (standard grade)

- Effective electrical insulation between layers

- UL94 V-0 flame resistance rating

- Cost-effective for mass production

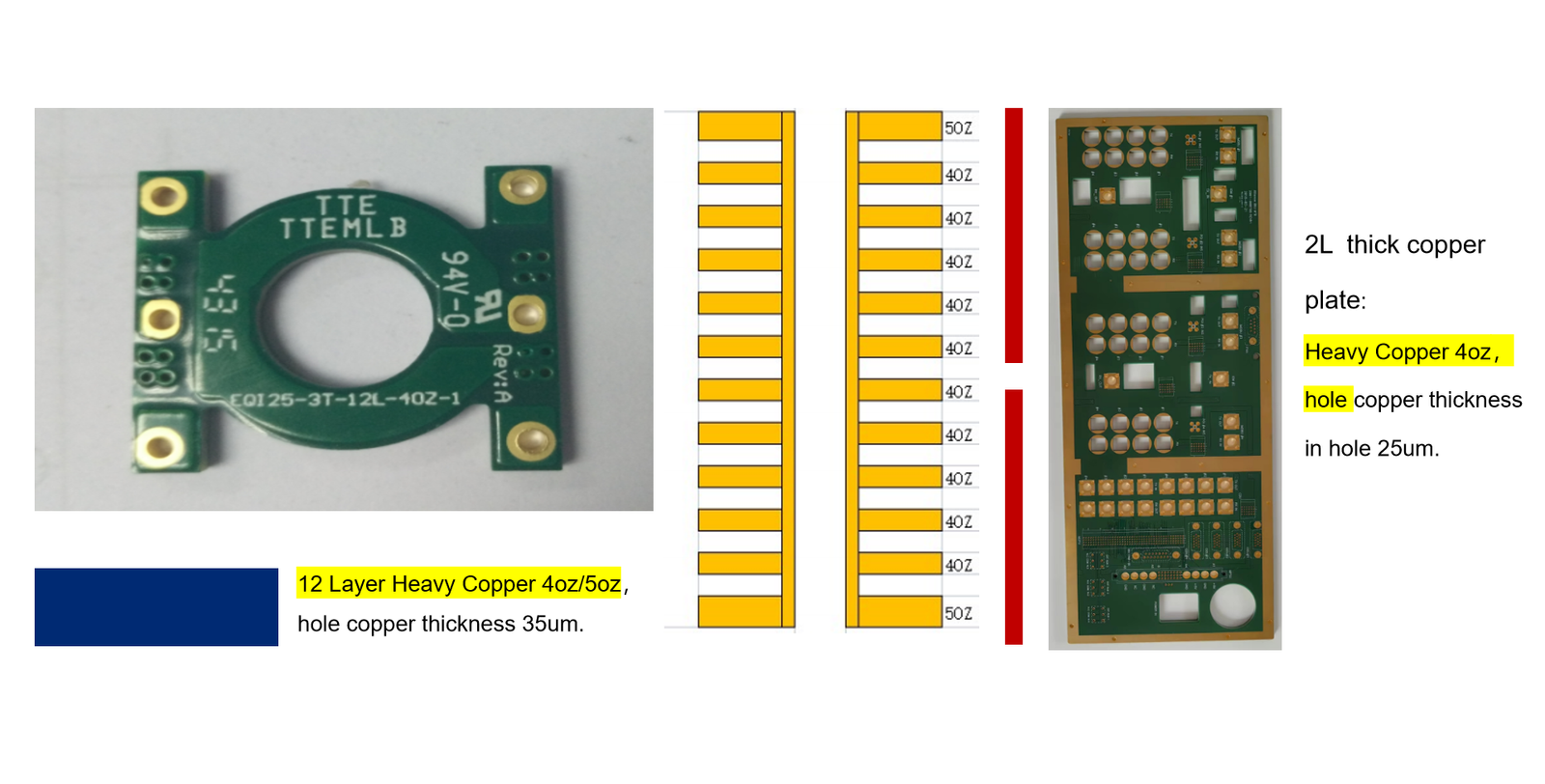

Common FR4 board thickness includes 0.8mm, 1.6mm, and 2.0mm. Most boards use copper cladding from 1 to 3 oz/ft².

Key Properties of FR4

| Property | Typical Value | Why It Matters |

|---|---|---|

| Glass Transition Temperature (Tg) | 130–150°C | Helps boards resist thermal shock during soldering |

| Dielectric Constant (Dk) | ~4.2–4.8 | Supports signal integrity for digital and analog signals |

| Flame Rating | UL94 V-0 | Meets safety standards for fire resistance |

| Moisture Absorption | ≤0.10% | Ensures electrical stability in humid environments |

Why FR4 Is Widely Used in PCB Manufacturing

Most engineers prefer FR4 because it offers a solid combination of electrical performance and manufacturability at a reasonable cost. Here’s why it continues to dominate the industry:

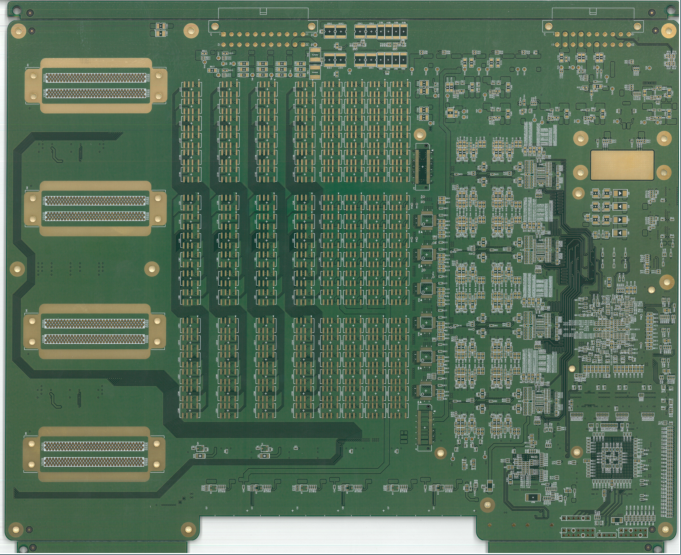

- Versatility: Works for single, double, and multilayer boards

- Cost Efficiency: Ideal for high-volume production runs

- Wide Availability: Easy to source from global suppliers

- Material Compatibility: Compatible with ENIG, HASL, OSP, and more

- Trusted Reliability: Performs well in consumer and industrial products alike

When to Consider Alternatives to FR4

Although FR4 covers most use cases, some applications push performance limits. Consider these alternatives when needed:

- For high-speed RF circuits: Choose PTFE or Rogers laminates with lower dielectric loss

- For high thermal demand: Use High-TG FR4 (Tg ≥170°C) or metal-core PCBs

- For extreme environments: Use polyimide substrates in aerospace or medical settings

- For high-power LED boards: Apply aluminum-backed or copper-core materials

If you’re unsure which substrate to use, our engineering team can recommend the best option based on your design and reliability goals.

Need Help Choosing the Right PCB Material?

Zhuhai Longyu supports global customers with expert guidance on PCB substrates.

Whether you need standard FR4, halogen-free, or high-TG solutions, we help you balance cost, compliance, and performance.

Summary

FR4 remains the standard PCB material because it performs reliably in most conditions while keeping costs under control.

When you understand its strengths and limitations, you make better decisions for your circuit design and manufacturing needs.